quad-Lock ICF

Australian Exclusive Authorised Dealer in Australia/NZ

Quad-Lock Building Systems is dedicated to improving our environment & well-being by offering sustainable building envelopes. Quad-Lock’s Insulating Concrete Forms (ICFs) for walls, floors and roofs create energy-efficient, comfortable, and safe buildings at a lower cost. Quad-Lock’s professional partners and staff pride themselves in providing excellent customer support from start to finish. Quad-Lock products are manufactured to the ISO 9001 quality standards and the ISO 14001 environmental standards.For more information on Quad-Lock contact us

There are four components of the Quad-Lock System to ensure simplicity in design, supply and construction. Quad-Lock can easily be shaped to form the design elements of modern buildings – openings, corners, angles, curves and arches. The salient features of Quad-Lock’s Building system are:

Simplicity – Quad-lock consists of 4 basic components and is easy to use

Versatility – The 4 components allow any design including curves and angles. Quad-Lock’s unique corner bracket system makes multi-story ICF construction easy, safe and efficient.

Strength – Quad-Lock uses the highest density foam in the industry and is the only system that connects the panels along 4 planes of resistance for superior formwork strength.

Energy Efficiency – Energy savings are documented to range from 40 – 70%.

Sounds Reduction – Quad-Lock walls achieve STC ratings of 50-58.

Everything you need about Quad-Lock/Quad-Deck

Insulated Concrete Forms For Walls

Build unlimited wall widths with many different insulation values, corners, angles, T-walls, columns, pilasters, and radius walls, using just a few standard components.

Panels made of Expanded Polystyrene (EPS) and Ties made of High Density Polyethylene (HDPE) create a Concrete Form that accommodates vertical and horizontal Reinforcing Steel as required.

Filling the cavity with concrete creates solid, reinforced concrete walls with 2-4 hour Fire Resistance Ratings (FRR), low maintenance, and outstanding durability. The EPS Forming System stays in place to provide space to run small utilities, serve as backing for finishes, and incorporate superior, continuous insulation layers. The high insulation values, low air infiltration, and high thermal mass can achieve significant energy savings for building owners, operators, and tenants over the building's longer lifetime.

Temporary bracing is usually required only for vertical and horizontal alignment.

Many different wall and insulation thicknesses are available using ties and panels of varying sizes. The Quad-Lock System encompasses these components:

• EPS Panels are available in 3 thicknesses, 4¼" [108mm], 3.125" [79mm], and 2¼" [57mm], giving you the choice of trueR-Values of 22, 28, 30, 38, 43, 45, 53, and 59 [metric U-values of 0.28, 0.20, 0.15 and lower].

• HDPE Ties are available in six standard lengths: Brown 18" [450mm] total nominal wall width, Red 16" [400mm], Green 14" [350mm], Yellow 12" [300mm], Blue 10" [250mm], and Black 8" [200mm] and they can be combined with the Orange Extender Tie to add another 12" [305mm] wall width.

• Corner, Angle, Window, and Straight Brackets eliminate bracing at corners and allow building EPS bucks or end caps.

• Metal Tracks & Wire Top Ties for starting and finishing the wall assembly

These components allow assembly of all concrete forming for your walls, including corners, arches, angles, columns, pilasters, as well as T-Wall connections. Transport and storage costs of Quad-Lock are substantially lower compared to pre-assembled block systems. Ordering and keeping track of inventory is easier (you would need at least 45 different parts to do the same with pre-assembled blocks).

Quad-Deck Insulated Concrete Forms For Floors, Roofs, And Tilt-Up

Benefits of ICF Floors and Roofs

Advantages for Owners:

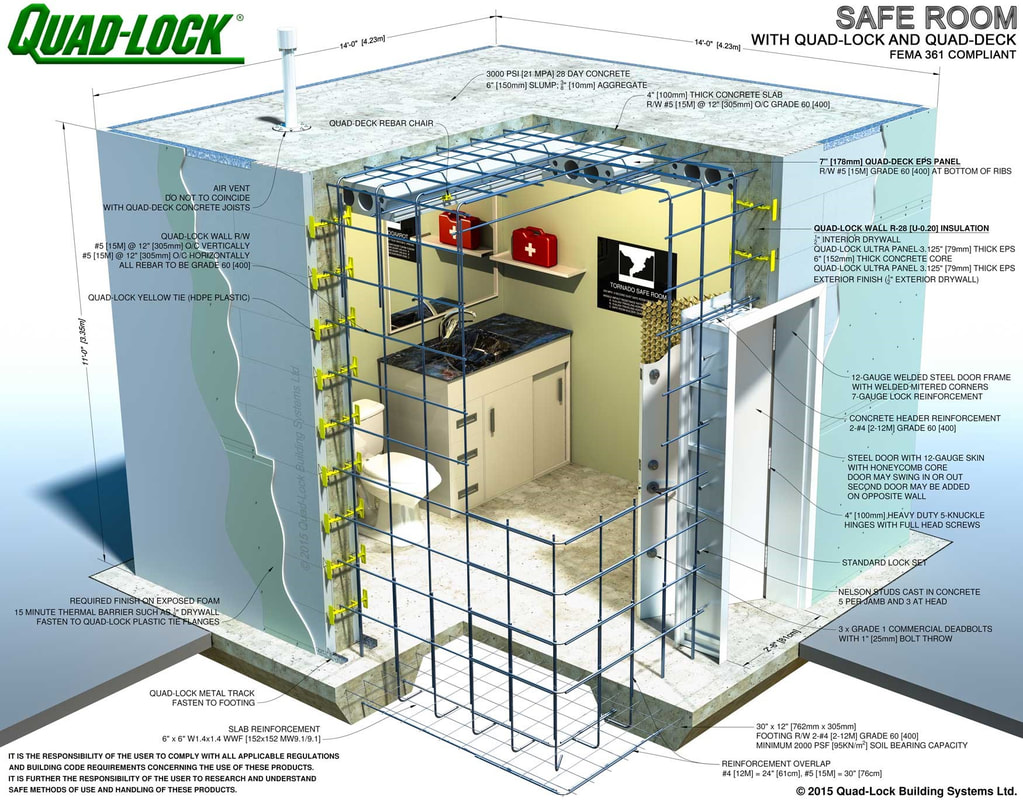

Quiet, Healthy, Safe & Comfortable • More consistent indoor temperatures • Perfect for in-floor radiant heating • High STC ratings; deadens sound transmission • Minimized air infiltration – fewer allergens, improved indoor air quality • Inert materials: doesn’t support the growth of mold or mildew • Rated Fire Resistance (using ACI216) • Not a food source for insects • Superior protection against catastrophic events – ideal for Safe RoomsDurable & Sustainable • High R-Values (R-16 to R-33); Low U-Values (0.35 to 0.17) • Reduced HVAC requirements, heating and cooling costs • Thermal mass properties; ideal for passive solar designs • Lower life-cycle costs • Long-term building durability; life-cycle measured in centuries

Advantages for Contractors & Architects:

Fast & Flexible • Lightweight, easy to handle – no forms to be stripped • Delivered to site ready to install – pre-cut at factory to exact specifications • Self-reinforced forms – temporary shoring only every 6′ • Available in thicknesses of 7″ to 12½”, up to 34′ [10.3m] free spans (and more with additional EPS caps or post-tensioning) • Slab thickness from 1¾” to 6″ [45mm to 152mm] • Easily integrates with Quad-Lock ICF systemLightweight • Lighter structure; eliminates 50% of conventional shoring • Reduces floor mass dead load by up to 50% • Reduces structural requirements for foundations and walls

Reduced Costs • No site waste • Uses less concrete & steel compared to traditional concrete slab • Lower workers-comp due to lightweight forms

Fact Sheet of R-Values on Quad-Deck Floors and Roofs

Quad-Deck Technical Summary

Quad-Deck Main Construction Steps

- Setup Shoring & Quad-Deck

2. Install Rebar & Pour Concrete

3. Remove Shoring & Finish it

R-ETRO High Performance Insulation System On Existing Buildings

- Save Money: Significantly reduces energy consumption

- Highest R-Value available in an insulation system

- The R-Value of EPS will not decrease with age

- Inhibits air infiltration

- It’s Easy: Faster and easier to install than other insulation systems

- For new construction or do-it-yourself renovations

- Built-in fastening system is superior to systems applied with adhesives

- Levels surfaces for finishing

- Built-in rain screen

- It’s Safe: No health risks in installation and use

- No CFCs, HCFCs. EPS will not mould, decay or rot

- Modified EPS includes a fire retardant

How it Works R-ETRO Ties are fastened to the existing building with screws at 24″ [610mm] centers*. EPS Panels are fit over the tie flanges and another row of R-ETRO Ties are placed in the tops of the panels at 24″ [610mm]. Panels can be easily cut around openings and protrusions from the building. Finish materials can be applied directly to the R-ETRO System or furring strips can be applied to the surface of the panels prior to finishing. * For areas with high wind-loads, please consult the R-ETRO System Product Manual

Fire Safe homes and rooms

More about Fire Safe homes and Rooms

Quad-Lock installation Training

For Builders, Architects, Engineers And Construction Companies – The Full Quad-Lock Insulated Concrete Forms (ICF) Installation Training.

Quad-Lock ICF Projects Globally - Case Studies

Quad-Lock ICF Technical Data

All information about Quad-lock and Quad-Deck, E-retro, Compliance, Manuals, Chapters videos and more:

Technical Library

Product Manuals

Installations videos

Building Codes Compliance

Insulated Concrete Forms (ICF)

Quad-Lock® is a panel-type ICF wall systemconsisting of panels, ties, metal tracks and metal brackets. Quad-Lock Panels are made with high-density, fire-retardant expanded polystyrene (EPS), which uses no formaldehyde, HFCs or CFCs. Five-panel types and eight types of plastic ties allow virtually limitless design options using standard components. R-values range from R-3.74 to R-11.11 – the highest in the industry.

Plastic ties ingeniously connect the panels and support the reinforcing steel while also providing a means to anchor drywall, siding and temporary bracing. The metal track is used to start and finish the walls, and metal brackets create the strongest corners in the industry, eliminating additional outside bracing at corners and angles. Metal brackets come in a 90° version, an adjustable version accommodating almost any wall angle, and versions for bucks / end-caps and buttress walls.

Applications include load-bearing walls, shear walls, fire-resistant walls, basement walls, retaining walls, and foundation walls incorporated in residential, industrial and institutional construction.

ICF for Floors & Roofs (Suspended Slabs)

Quad-Deck® uses patented technology to create an energy-efficient and quality insulating concrete floor or roof system. Ideal for use in both commercial and residential construction, Quad-Deck combines the strength, security and reliability of concrete with the energy efficiency, design flexibility and comfort of insulating concrete forms.

Quad-Deck panels shape a series of T-beams every 24″ [610mm], which integrate with a concrete slab. The resulting monolithic concrete structure provides a two-way span capacity and a shear plane for superior structural performance using less concrete & less time.

ICF for Tilt-Up Applications

The Quad-Deck Tilt-Up solution is a lightweight form used to create panelized, reinforced concrete walls for tilt-up construction. The forms stay in place to deliver an integrated, insulated wall system. Each EPS panel is supported and reinforced with two integral steel beams molded into the product from end to end. The result is a self-supporting system that provides the maximum strength of a reinforced concrete wall with a minimum of materials and labour.

Retrofit Insulation for existing buildings.

Quad-Lock is pleased to announce the launch of a new insulation system aimed at the renovation market. The R-ETRO System is a fast, flexible, non-invasive form of Insulation that adds R-Values of R-10, R-18, or R-26 to existing wall surfaces. The system easily adapts to the shape of an existing building and around protrusions and openings. It can be attached to any wall structure: wood, concrete, steel, brick or masonry block.

Insulated Concrete Forms For Swimming Pool Walls